There have been massive developments in the industrial sector in India including the oil and gas industries, petrochemicals, pharmaceuticals and power. Pressure vessels are a very important component of these industries. The pressure vessel and the heat exchanger are high quality equipment whose demand is on the increase as India establishes itself as a manufacturing hub among the world.

The next factor to consider when selecting a manufacturer of reliable pressure vessels in India is to ascertain safety and efficiency as well as international standards. This is a detailed handbook of the leading Pressure Vessel Manufacturer in India who are benchmarking the industry.

What is a Pressure Vessel?

A pressure vessel is a specially designed container which is specifically engineered to retain gases or liquids with much different pressure than that of the ambient atmospheric pressure. They are strong containers which could be cylindrical, spherical as well as conical in shape and have been constructed to be resistant to the extreme environment.

Use of pressure vessels can be in storage of compressed air used in manufacturing plants and storage of dangerous chemicals in refineries, among other uses. They are also produced with the best materials such as carbon steel, stainless steel and exotic alloys, under rigid codes of design such as ASME Section Eight which guarantee structural integrity and operational safety.

Importance of Quality and Safety Standards

- Life Safety: Poor quality ships have threats of exploding which may result in deaths and serious injuries.

- Regulatory Conforms: ASME, IBR, and international code of rules allow avoidance of legal liability.

- Operational Efficiency: Operational is reduced in quality vessels because it reduces downtime and costs of maintenance.

- Environmental Protection: The proper containment has avoided leaks of dangerous materials.

- Asset Longevity: Excellence in manufacturing is guaranteed, which means that equipment will last long.

- Cost Effectiveness: Quality vessels have lesser replacement rates and less operational failure.

Types of Pressure Vessels & Related Equipment

- Storage Vessels: These are used in the storage of gases and liquids at definite pressures.

- Heat Exchangers: This is used to transfer heat among two or more fluids.

- Reactors: Chemical reaction vessels under controllable pressure and temperature.

- Distillation Columns:Divide mixtures in liquids by their volatility.

- Autoclave: This is a high-pressure sterilization and chemical vessel.

- Air Receivers: reservoirs used to store pressurized air that is used in pneumatic systems.

- Separators: No purification of process streams.

Challenges in the Indian Pressure Vessel Manufacturing Industry

- Material Cost Fluctuations: Steel prices are volatile at the global level and this has an implication on manufacturing costs.

- Proficient workforce deficit: Requirement in registered welders and quality surveyors.

- Technology Upgradation: Constant investment in newly-modern equipment of fabrication.

- Strict Quality Standards: The concept of meeting global standards requires high levels of testing.

- Threat of Substitute: Competition through foreign suppliers.

- Regulatory Compliance: Going through convoluted local and global certification procedures.

- Delivery Timeline Pressures: Quality versus project deadline pressure

Quality Standards & Certifications to Look For

- ASME U, U2, R Stamps: Certifications of the American Society of Mechanical Engineers on pressure vessels.

- IBR Approval: compliance with Indian Boiler Regulations of boiler and pressure equipment.

- Freudenrich and Vonderembse 241: Quality management as an element of human resources management.

- NACE Certification: In oil and gas oil and gas corrosion control.

- PED Certification: European market Pressure Equipment Directive.

- Third-Party Inspection: Approaches at Lloyds, TUV, DNV-GL, ABS.

- NBIC S-Stamp: National Board Inspection Code of repairs and alterations.

Also Read: listed electric bus manufacturers in india

Top 10 Pressure Vessel & Heat Exchanger Manufacturers in India

1. Godrej & Boyce Manufacturing Company Limited

- Founded In: 1897

- Address: Pirojshanagar, Vikhroli, Mumbai – 400079, Maharashtra, India

- Website: www.godrej.com/godrejandboyce

- Ph No: +91-22-6796 5656 / 5959

Godrej & Boyce is the most reputed industrial conglomerate in India of engineering excellence for more than 125 years. This is a flagship organization of the Godrej Group that is engaged in 10 different industries, which have about 14,000 professionals. They are the biggest Pressure Vessel Manufacturer in India, which also provides high-end custom-engineered solutions to the key areas of use, such as aerospace, defense, and power generation, with more than a billion customers worldwide.

Key Products & Services:

- Chemical and pharmaceutical high pressure reaction vessels.

- Nuclear and defense pressure vessels designed to order.

- Specialty heat exchanger-generation plants.

- Refiners storage tanks and refinery process equipment.

- Complete installation solutions in terms of turnkeys.

Why Choose Them: Over 125 years of experience and being relied upon by all the most successful industries in the world.

Also Read: Electronics Companies in India

2. Tinita Engineering Private Limited

- Founded In: 2006

- Address: R-266, Thane-Belapur Road, T.T.C. Industrial Area, Rabale, Navi Mumbai – 400701, Maharashtra, India

- Website: www.tinitamfg.com

- Ph No: +91-22-50441001

Tinita Engineering has become one of the main Pressure Vessel Manufacturer in India that manufactures ASME-certified equipment to be used in the cases of corrosive and high-pressure. They have offices in Navi Mumbai and Dahej and have already shipped more than 3,000 units of equipment in 13+ countries. They are also a good choice especially in difficult to make applications in petrochemicals and specialty chemicals due to their expertise in the use of exotic materials such as titanium, zirconium and tantalum.

Key Products & Services:

- ASME U, R, NB stamped pressure tanks to 500 bar.

- Shell and tube heat exchangers made of exotic materials.

- Clad pressure vessels (explosion bonding, roll cladding).

- Pharmaceutical and specialty chemical industries chemical reactors.

- Premade columns and storage tanks, custom-made

Why Choose Them: Due to Them being an ASME-qualified manufacturer with knowledge in exotics, as well as corrosion-resistant unpainted equipment.

3. Sieco Engineers Private Limited

- Founded In: 1988

- Address: 125B, Bommasandra Industrial Area, Hosur Road, Bangalore – 560099, Karnataka, India

- Website: www.siecoengineers.com

- Ph No: +91-80-4122 0701 / +91-80-41200659

Sieco Engineers is an example of an engineer that manufactures pressure vessels in India with a history of more than three decades of turnkey services. They are certified on ISO 9001:2015 and are excellent in delivering end to end solutions. Their high level of welding automation and CNC machining facility allows them to cope with a complex high-pressure environment whose pressure is more than 100 kg/cm 2.

Key Products & Services:

- Extreme pressure high-volume pressure vessels.

- Multi shaft mixers and grease kettles.

- High-energy stirring reaction reactors.

- Automated turnkey welding.

- The equipment construction and installation of the plant processes.

Why Choose Them:It is an ISO certified manufacturer with established welding automation and 30 plus years of experience in turnkey projects.

4. Amar Equipment Private Limited

- Founded In: 1974

- Address: Valson Textile Mills, LBS Marg, Bhandup West, Mumbai – 400078, Maharashtra, India

- Website: www.amarequip.com

- Ph No: +91-22-2564 7656

Amar Equipment was the first to manufacture high pressure equipment in India; it has become one of the pioneers in the country as well as in the world. They are the largest pressure vessel manufacturer of lab scale to pilot plant reactor systems that design up to 700 bar pressure and 600 C temperature. They can use ASME U stamps and are certified with ISO 9001: 2015 and have more than 1,000 satisfied clients operating in 50 countries, the company focuses on research and development applications.

Key Products & Services:

- Autoclaves and reactors (up to 700 bar) High pressure.

- Process intensification reactors: continuous flow.

- The systems of magnetic drive coupling with zero-leakage.

- Super-critical fluid extraction.

- Automated turnkey pilot plants.

Why Choose Them: The biggest high-pressure autoclave manufacturers in India since 1974, having zero-leak magnetic drive technology.

5. Pressure Vessels India (PVI)

- Founded In: 1980

- Address: J-499, MIDC Bhosari, Pune – 411026, Maharashtra, India

- Website: www.pressurevesselsindia.com

- Ph No: +91-20-2710 2156

The company Pressure Vessels India has established its market as a localized supplier of pressure vessels within India, whose expertise on heavy pressure vessels and columns, reactors, and heat exchangers amounts to more than 40 years to date. Certified to ASME U, R, and NB they work with such prestigious customers as ONGC, ESSAR, or SUEZ. Since the introduction to the FABCONS family in 2016, PVI has grown in skills and quality excellence in undertaking complex industrial projects.

Key Products & Services:

- Massive pressure vessels having a wall thickness of up to 80mm.

- TEMA class R, C B and B heat exchangers.

- Dist. columns (ani. 5m dia × 50m high).

- Wet H2S service heat exchangers that are compliant with NACE.

- Petrochemical reactor vessels.

Why Choose Them:ASME-qualified heavy pressure vessel expert with 40 plus years of service to large oil and gas corporations.

6. Syscon Engineers

- Founded In: 1995

- Address: 206/207, Dhanalaxmi Service Ind. Estate, Above Navneet Motors, LBS Marg, Thane (W) – 400601, Maharashtra, India

- Website: www.sysconengineers.com

- Ph No: +91-251-2620293 / 2621303

Syscon Engineers has become a dominant Pressure Vessel Manufacturer in India in the oil, gas, chemical and pharmaceutical equipment. They have a fabrication capacity of 1, 000 tons per annum, and are good in designing and supplying customized equipment according to Indian and International standards. They also have the capability of lead-lined and rubber-lined vessels and therefore they are a general solution provider in the industry in terms of corrosive application.

Key Products & Services:

- Custom pressure vessels ASME and Indian.

- Lined Corrosion-resistant vessels are lead-lined or rubber-lined.

- Crystallizers and multi-effect evaporation systems.

- Column reactive models and chemical reactors.

- Erection and commissioning Turnkey project solutions.

Why Choose Them: The focus of their business is on the corrosion-resistant lined vessels and turnkey project implementation.

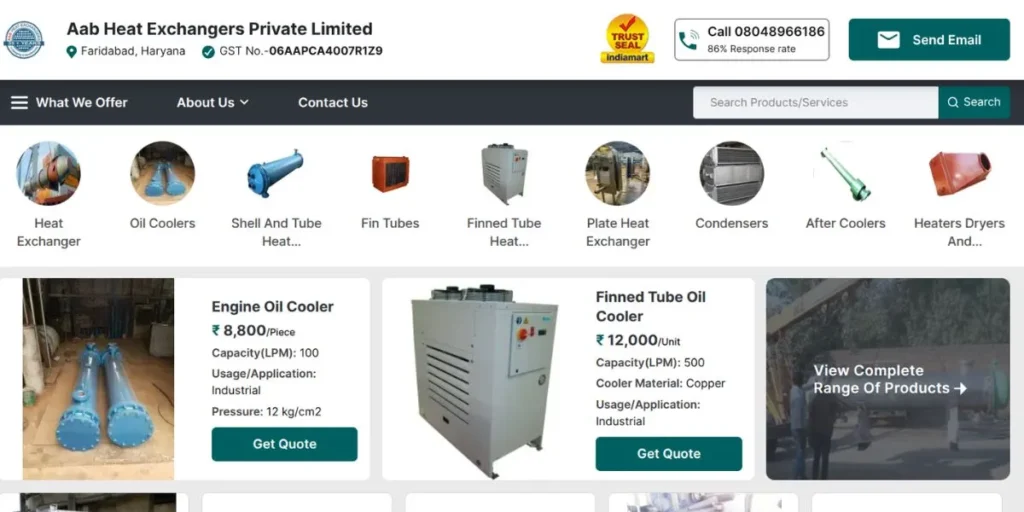

7. AAB Heat Exchangers Private Limited

- Founded In: 1982

- Address: 375, Industrial Plot, Sector 24, Faridabad – 121005, Haryana, India

- Website: www.aabheattransfer.com

- Ph No: +91-129-4174674

AAB Heat Exchangers has established its world-renowned reputation in Pressure Vessel Manufacturer in India over almost 40 years of manufacturing superiority. They produce a variety of heat exchangers, pressure vessels and industrial coolers, with their products also having ISO 9001: 2008 certification and HTRI software license. The long experience they have lets them give personalized solutions that fit the precise requirements of the clients with the provision of repair and reconditioning services to the current equipment.

Key Products & Services:

- Shell and tube (all TEMA standards) heat exchanger.

- Air receivers and industrial pressure vessels.

- Oil coolers, intercoolers and aftercoolers.

- Finned tube heat exchanger and condensers.

- Repair services, reconditioning services and maintenance services to equipment.

Why Choose Them: licensed manufacturer of HTRI, over 40 years of experience in heat transfer, and after sales services.

8. Stalwart International

- Founded In: 1998

- Address: Plot No. 101-103, Phase-1, GIDC, Vatva, Ahmedabad – 382445, Gujarat, India

- Website: www.stalwartint.com

- Ph No: +91-79-2583 0734

Stalwart International is one of the manufactures of pressure vessels in India and among the top leading manufacturers of pressure vessels in the state of Gujarat and has high-quality equipment serving chemical, pharmaceutical, and specialty chemical industries. Their high quality control practices and ethic to excellence have granted them approved status as a vendor with many sources of fortune 500 companies. Having the capabilities of supporting the pressure up to 700 bar and temperature to 600C, they provide the reliable solutions to the challenging applications.

Key Products & Services:

- Chemical and pharmaceutical high pressure vessels.

- Process equipment and stainless steel reactors.

- Specialty chemical heat exchangers.

- Bins and process vessels of exotic material.

- Installation and complete maintenance services.

Why Choose Them: Certified supplier of fortune 500 firms that offer strict quality standards and workmanship.

9. Rajog Engineering

- Founded In: 1985

- Address: Plot No. C-21, MIDC Industrial Area, Ahmednagar – 414111, Maharashtra, India

- Website: www.rajog.in

- Ph No: +91-241-2323456

Rajog has been a reliable manufacturer of pressure vessels in India with many decades of experience in engineering. They are the experts in designing, production, and distribution of pressure vessels that meet international requirements such as ASME, API and IS standards. Their state of art manufacturing plants use modern sophisticated CAD software and modern fabrication technologies resulting in the optimum design, maximum efficiency, and safety of all their pressure vessel products.

Key Products & Services:

- ASME, API and IS pressure vessels which are code-compliant.

- Different storage tanks of different capacities and specifications.

- Oil and gas heat exchanger.

- Chemical processing reactor vessels.

- Engineer-designed solutions and high superiority testing.

Why Choose Them: Scores of experience and thorough compliance with all standards of international design and advanced production.

10. ABE & HEX India Private Limited

- Founded In: 2009

- Address: Plot No. 58, Sector 63, Noida – 201301, Uttar Pradesh, India

- Website: www.abehex.com

- Ph No: +91-120-4377800

ABE and HEX (previously AB Engineers) has quickly emerged as a reliable manufacturer in India of pressure vessels with focus on heat exchangers, industrial condensers, as well as pressure vessels. They are established by strong visionary partners particularly having good knowledge of the industry and use superior technology to offer products that are up to the international levels. Their Quality Assurance policy, which guarantees that each of their units goes beyond the industry standards, makes them the choices of heat transfer solutions within various industries.

Key Products & Services:

- Conditioners and shell and tube heat exchangers.

- Tube bundles and industrial pressure vessels.

- Shell and tube evaporators and coolers.

- Developed solutions Custom solutions with custom heat exchangers.

- Competitive prices and the products that pass quality assurance.

Why Choose Them: High technology based manufacturing and quality that will surpass any industry standard and fast delivery.

How to Choose the Right Pressure Vessel Manufacturer

- Certifications & Compliance: ASME, IBR, ISO Certifications, and third-party inspection approvals, etc.

- Technical Expertise: Evaluate design skills, prowess of materials and engineering assistance.

- The Capacity to manufacture: assess the manufacturing plants, machinery and transportation capacities.

- Quality Assurance: Survey testing processes, quality assurance systems, and paperwork.

- Experience & Track Record: Experience in the industry, client references, and Project portfolio.

- After Sales Services: Take into consideration maintenance services, availability of spares and technical support.

- Delivery Schedule: verify achievable production schedules and record of delivery on schedule.

- Cost Competitiveness: Compare quotes and still not compromise on the quality standards.

Conclusion

The pressure vessel manufacturing sector has evolved and the companies are competing at the international level in terms of quality, technology and service. The above manufacturers are the best of the best in this industry and have their own strengths and specialization. Regardless of whether you require high-pressure laboratory autoclaves or heavy industry reactors, these options of pressure vessels manufacturers in India offer are the best in the world.

Cost is not the sole criteria that should be used when choosing a manufacturer; safety certifications, technical knowhow, and track records should also be looked into. The correct partner will guarantee you not only the short-term project success but the reliability and safety of your operations in the long run of your critical industrial processes.

Check it out:- Indian toy industry

FAQs

How long is the median of the lead times of the Pressure Vessel Manufacturer in India?

8- 16 weeks usually depending on the complexity, availability of materials and testing. Other specific exotic material containers can also require 20-24 weeks.

Are you able to export pressure vessels that are ASME certified by Indian manufacturers?

Indeed some Indian manufacturers are certified with ASME U, U2, R and NB stamps which allow them to provide internationally acceptable pressure vessels that can be sold in the international markets.

What are the materials that are widely applied in the manufacturing of pressure vessels?

Corrosive applications using carbon steel, stainless steel (304, 316, 316L), duplex and super duplex steel, and exotic alloys such as Hastelloy, Monel, Titanium, Zirconium and Tantalum.

What is the frequency with which the pressure vessels should be tested and inspected?

According to the requirements of the regulations, it is usually internal inspections with hydrostatic testing once in 3-5 years, although the frequency depends on the conditions of the service and local norms.

What are the cost considerations in the process of ordering the pressure vessels?

Costs of materials, complexity of fabrication, testing, certifications required, shipping schedule, installation, and after sale service -not only the first-purchase cost.